Written by: LIANG Yingshuang

Translated by: WANG Ziyun

Edited by:William Mosteller

Date: 04-10

Harbin Institute of Technology News (written by Tian Hao ) Recently, Professor Tian Hao andProfessor Zhou Zhongxiang of the School of Physics in HIT, along withAssociate Professor Wang Ke and Professor Li Jingfeng of the School of Materials Science and Technology in Tsinghua University, cooperated to report articles on high-performance lead-free piezoelectric single crystals of potassium sodium niobate(KNN). Relevant research results are titled "Ultra-large electric-field-induced strain in potassium sodiumniobate crystals" and were published online in March 2020 in the internationally renowned academic journal Science Advances.

Piezoelectric materials are a class of important information functional materials that can realize the conversion between mechanical energy and electrical energy. They have a broad application foundation in the fields of micro-electromechanical systems (MEMS), energy recovery, medical diagnostics, wireless communication, and other fields. The global market for piezoelectric materials and devices has exceeded $25 billion in 2019 [1], among which lead-containing piezoelectric materials, represented by lead zirconatetitanate(PZT),occupied the majority of the market share. The EU RoHS directive stipulates that the use of lead-based piezoelectric materials in electronic and electrical products may not be exempted from [LM1] 2021. The lead-free replacement in some application fields will be a new track for the industrial application of materials in the future electronic industry. The current market scale of global lead-free piezoelectric materials is growing at a rapid annual compound growth rate of 20.8%, and is expected to be over $400 million by 2024[1].

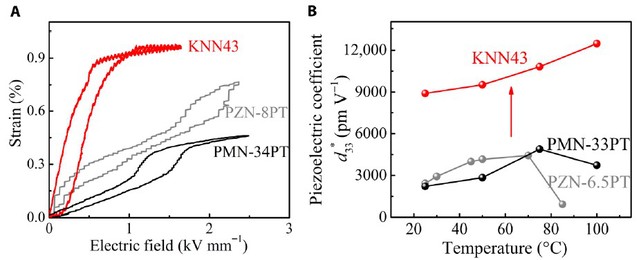

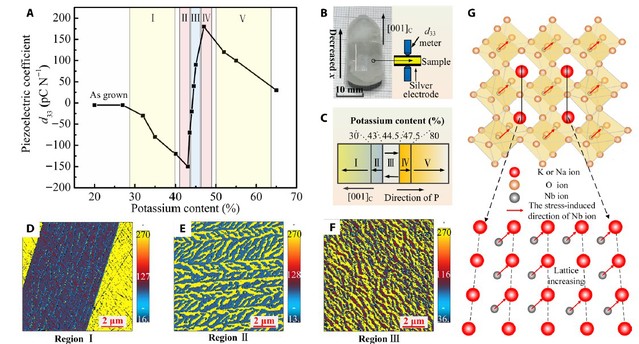

In recent years, there have been numerous studies on lead-free piezoelectric materials, among which potassium sodium niobate piezoelectric material (K1-xNaxNbO3, KNN for short) shows its huge development potential due to its high piezoelectric coefficient and Curie transition temperature. The research team of Professor Tian Hao and Professor Zhou Zhongxiang innovatively used the composition gradient in the single crystal growth process to grow a high-quality KNN single crystal with a controllable composition gradient. The crystal material has an electric field strength of up to 0.9% at 1kV/mm. The strain performance achieved a large signal piezoelectric coefficient of up to 9000pm / V (Figure 1). In addition, the piezoelectric performance of the crystal does not weaken with temperature in the range of 25°C to 125°CC[LM2] , showing excellent temperature stability, and the overall performance is far superior to lead-based single crystal.

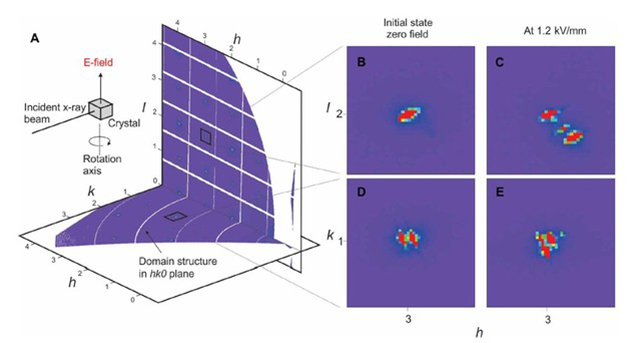

By using in-situ high energy X-ray diffraction, the research team confirmed that the high-voltage electrical property is due to the reversal of non-180°domain (Figure 2). By observing the domain and polarization characteristics of a series of crystals along the composition gradient, the research team found that the super large piezoelectric response only exists near the crystal material with a potassium/sodium ratio of 43/57, and the domain structure in this region presents a complex herringbone (Figure 3).

[LM1]Usually “exempt from” is followed by something (ex: exempt from jury duty.) I’m not quite clear what the meaning of this sentence is.

Do you mean that the use of lead-based piezoelectric materials in electronic and electrical products must cease by 2021?

[LM2]Do you mean just “C”?

Figure 1 shows the piezoelectric properties of KNN crystal material (kn43). GraphA shows theelectrostrain of kn43 crystal at room temperature, incomparison with other lead based materials; GraphB shows the temperature dependence of d33 * of different materials.

Figure 2 is a diagram of the in-situ reciprocal space of the crystal. Figure A is a schematic diagram of the data collection geometric space in the initial state, the hk and hl planes in the inverted space; Figures B and C show the change of the 302 diffraction peak before and after the electric field; Figures D and E show the change of the 310 diffraction peak before and after the electric field.

Figure 3 shows the piezoelectric properties and domain structure of the KNN crystal. Figure A is the change of piezoelectric coefficient d33 with potassium content; Figure B is a KNN crystal; Figure C is a schematic diagram of the macroscopic spontaneous polarization direction with composition; the domain structure of crystals with different K content is shown in Figures D-F(D 0.37, E 0.43 and F 0.45); Figure G is a schematic diagram of the recovery force of electric domain flipping induced by the composition gradient.

Dr. Hu ChengpengandDr. Meng Xiangda of HIT and Zhang Maohua, a graduate of Tsinghua University, are the co-first authors of the paper. The collaborators involved in this study also include Professor John E. Daniels of the University of New South Wales, Professor Li Li of Harbin Engineering University, and Professor LYU[LM1] Qieni of Tianjin University. This research work was supported by the National Natural Science Foundation of China and other projects.

In addition, in January this year, Professor Tian Hao and doctoral student Wang Yu collaborated with the research team of Xi’an Jiaotong University Li Fei, Professor Xu Zhuo, and Professor Chen Longqing of Pennsylvania State University in the United States to report on the research of transparent high-performance piezoelectric materials in Nature Latest [LM2] results. The research team prepared a relaxed ferroelectric single crystal with high-voltage electric and electro-optical effects and near-theoretical limit light transmittance through AC polarization.(Transparent ferroelectric crystals with ultrahigh piezoelectrity, Nature, 2020, DOI: 10.1038/s41586-019-1891-y).

Thesis link:https://advances.sciencemag.org/content/6/13/eaay5979

Reference:[1] M. Gagliardi, Am. Ceram. Soc. Bull. 99,7 (2019).