Written by: Aerospace Institute

Translated by: Zhou Dongyi

Edited by: D. Parker

Date: 2018-3-15

Professor He Xiaodong and Professor Wang Rongguo of the Institute of Composite Materials and Structures, and the Institute of Astronautics are leading the way in progress in the construction of the rapid and reversible conversion of super-wetting materials. The research results were published in "Advanced Functional Materials" (influencing factor: 12.124). The first author was Dr. Ding Guomin, and Professor Wang Rongguo and Jiao Weichen. The instructors, were the co-corresponding authors. The study was funded by the National Natural Science Foundation of China and the Youth Top Talent Selection Program of our school. HIT was the only signatory unit for this paper.

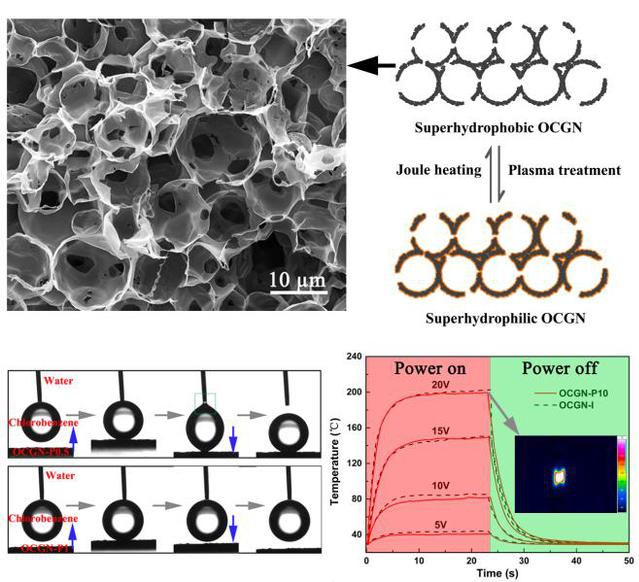

What is “super-wetting material?” The lotus leaves in nature have strong water-repellent properties; water droplets can roll freely from them. On the contrary, some moss-like plants, such as peat moss, have a strong hydrophilic ability, enabling them to directly absorb water to survive. Materials having super water repellency (super hydrophobic) prepared with these biomaterials are collectively referred to as super-wetting materials. Super-infiltrated materials are widely used in our daily lives. For example, an umbrella sheds raindrops immediately. The surface of the umbrella is made from a super-hydrophobic material, and the anti-fog mirror surface is generally coated with a super-hydrophilic material, making water vapor. Water film cannot be formed on the surface. However, a uniform water film is formed so that an antifogging effect can be achieved. Under certain external conditions, such as ultraviolet light irradiation, plasma treatment or temperature control, materials may be capable of reversible conversion between super hydrophobic and super hydrophilic. These materials are called “reversible super-wetting”. With the controllability of infiltration, this "smart switch" is of great significance in many areas of research such as micro fluidics, self-cleaning materials, submerged oil filtration, transport and collection. It has become one of the most important recent development directions in today's infiltrating studies. However, due to limitations of current technology, materials with reversible super-wetting capabilities still face problems such as long conversion time and a complicated conversion process. This seriously restricts the development and application of such materials.

Prof. He Xiaodong and Prof. Wang Rongguo developed a super-hydrophobic material OCGN through Pickering emulsion technology and a simple method of steam overflow. The material can be converted from a super-hydrophobic state to a super-hydrophilic state after plasma treatment for 1s, which significantly shortens the conversion time (see the literature for the shortest conversion time of 25s). In addition, the ultra-hydrophilic OCGN exhibits super- hydrophobicity under water, and its adherence to underwater oil droplets is controllable. This characteristic can be used to complete the directional transportation of oil droplets underwater. At the same time, the material also has the characteristics of heat conduction, and it can only reach a high temperature in a short time under the conditions of the application of low voltage. Combining electro-thermal characteristics, the team used Joule heat for the first time to achieve ultra-fast recovery of OCGN surface super-hydrophobicity in a minimum of 1 minute. This kind of super-wetting material with rapid reversible conversion has a broad application prospect in the field of super-wetting surfaces.

It is worth mentioning that the research group has also made a number of research achievements in the micro structure design, controllable preparation and functional research of graphene-based composite materials. Previously, a zero-dimensional graphene-based composite material with high sensitivity to gas sensing has been successfully prepared (J. Mater. Chem. A. 2016, 4, 8198.); the one-dimensional graphite capable of rapidly detecting gas has been developed (Carbon. 2015, 95, 34); a three-dimensional graphene-based closed-cell microsphere grading material with high adhesion and self-sensing ability for water droplets have been designed and prepared (J. Mater. Chem. A. 2017, 5, 17325) as well as graphene aligned enhanced microstructure ordered composites (Compos. Sci. Technol. 2014, 99: 124 and J. Mater. Chem. C. 2017, 5, 6359).