A research team led by Professors Qian Zhang and Jun Mao from the Harbin Institute of Technology (HIT) Shenzhen Campus has achieved a major breakthrough in thermoelectric materials, developing a room-temperature magnesium bismuthide (Mg₃Bi₂) single crystal that combines exceptional plasticity with high thermoelectric performance. Published in Nature, the study opens new avenues for flexible wearable electronics and energy-efficient heat-to-electricity conversion technologies.

The Quest for Plastic Thermoelectrics:

Thermoelectric materials, which convert heat directly into electricity (via the Seebeck effect) or enable precise cooling (via the Peltier effect), are critical for applications like 5G laser cooling and waste heat recovery. However, traditional inorganic semiconductors—while efficient—are brittle and prone to fracture under bending. Organic alternatives, though flexible, lag in performance. Bridging this gap requires materials that defy the trade-off between mechanical deformability and thermoelectric performance.

A Material with Dual Superpowers:

The team synthesized centimeter-sized Mg₃Bi₂ single crystals that defy expectations:

1. Unprecedented Plasticity: The material withstands compressive strains exceeding 75% and tensile strains up to 100%—surpassing conventional thermoelectric materials by an order of magnitude and even outperforming metals like titanium, magnesium, and cobalt.

2. High Thermoelectric Performance: Tellurium-doped Mg3Bi1.998Te0.002 achieves a room-temperature thermoelectric power factor of 55 μW cm-1 K-2 and a figure of merit (zT) of ~0.65, rivaling state-of-the-art plastic thermoelectric materials.

The Science Behind the Plasticity:

Transmission electron microscopy revealed that Mg3Bi2’s plasticity stems from abundant slip bands and dislocations formed during deformation. First-principles calculations identified low-energy slip systems (prismatic, basal, and pyramidal planes) and dynamic bonding processes that prevent cleavage. These mechanisms allow atomic layers to slide smoothly without fracturing, akin to metals, while retaining semiconductor-like electronic properties.

Implications for Next-Gen Devices:

"This material redefines what’s possible for plastic thermoelectrics," said Professor Zhang. "Its dual capabilities could revolutionize wearable energy harvesters, stretchable sensors, and conformal cooling systems for electronics." The team’s work also provides a design blueprint for discovering other plastic semiconductors by leveraging weak chemical bonding and multi-slip systems.

By harmonizing mechanical properties with energy conversion efficiency, Mg3Bi2 sets a new benchmark for plastic thermoelectrics.

Paper link: https://www.nature.com/articles/s41586-024-07621-8

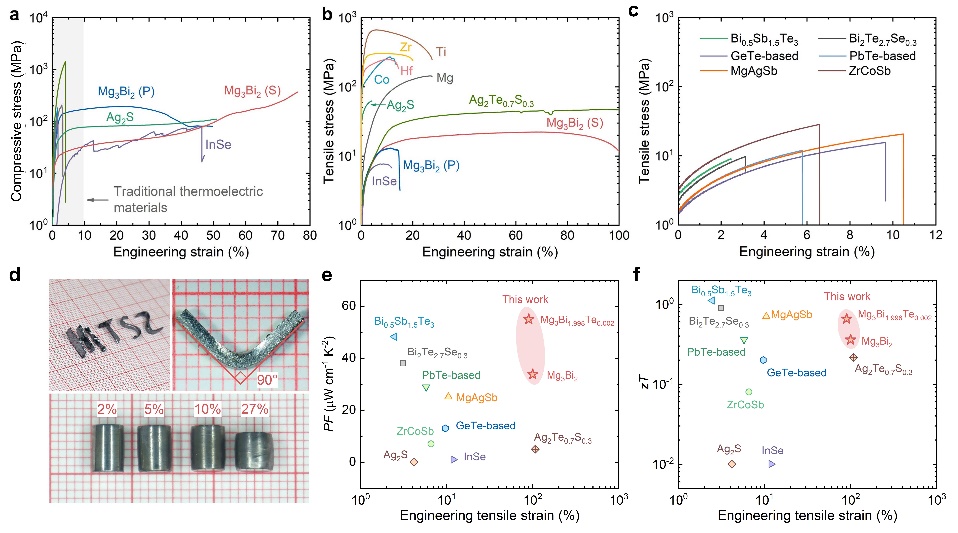

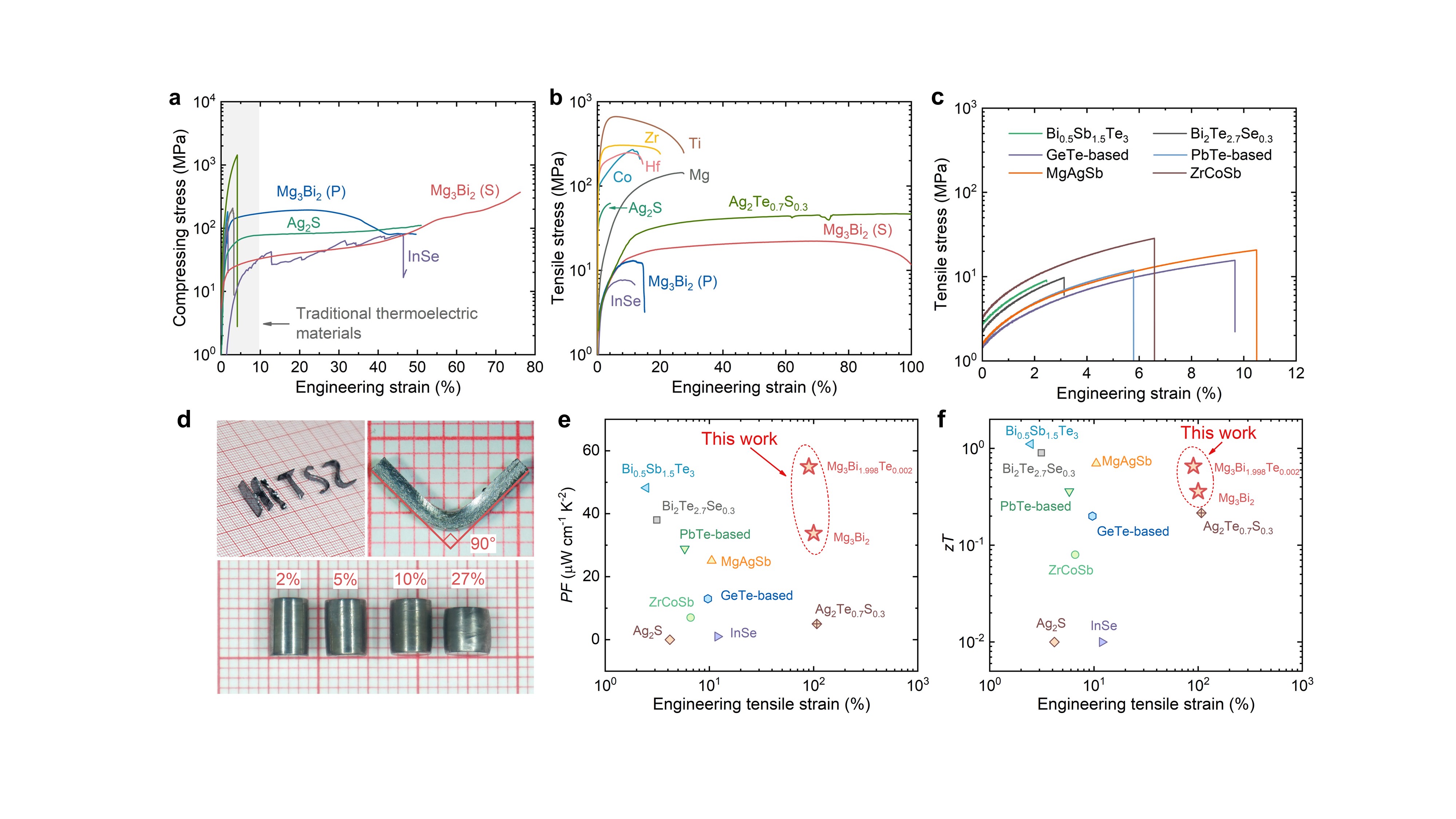

Figure 1

Fig. 1 Plastic deformability of Mg3Bi2. (a) Compressive stress-strain curve of different thermoelectric materials and ductile semiconductors. (b) Tensile stress-strain curve of different hexagonal close-packed metals and ductile semiconductors. (c) Tensile stress-strain curve of traditional thermoelectric materials. (d) Morphed single-crystalline Mg3Bi2 to exhibit the letters “HITSZ”, bent single-crystalline Mg3Bi2, and comparison of the bulk polycrystalline Mg3Bi2 with different compressive deformation. Comparison of the relationship between the maximum engineering tensile strain and room-temperature (e) power factor and (f) zT among the different thermoelectric materials.

Figure 2

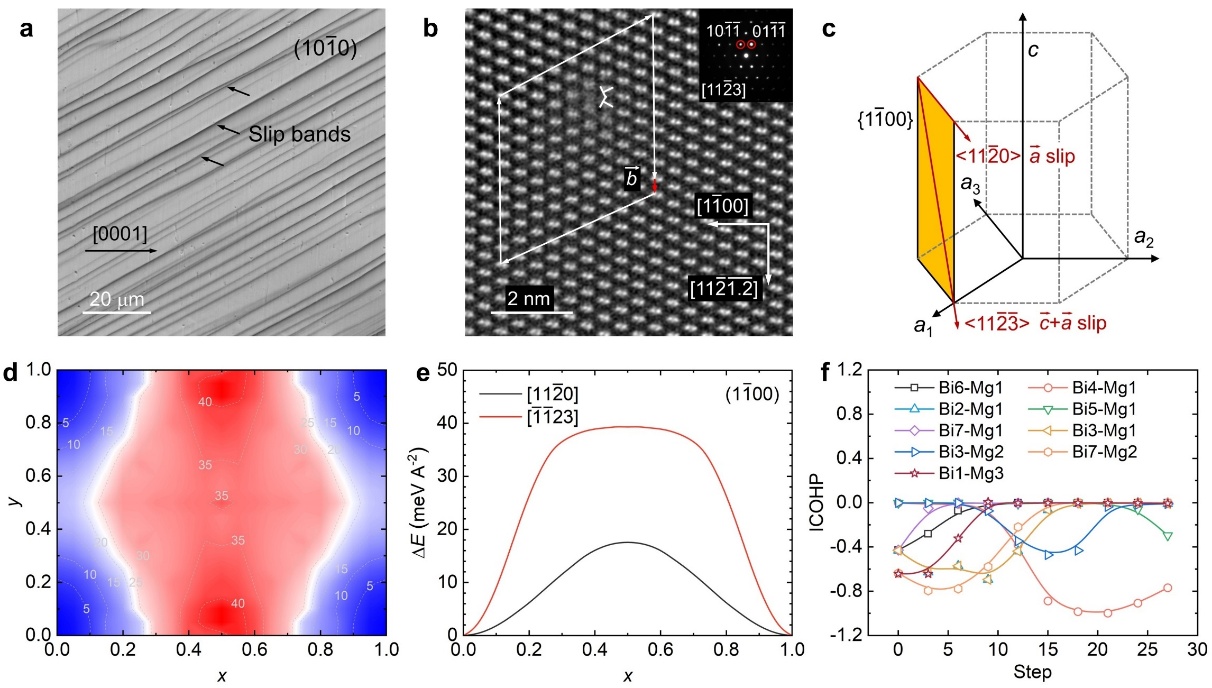

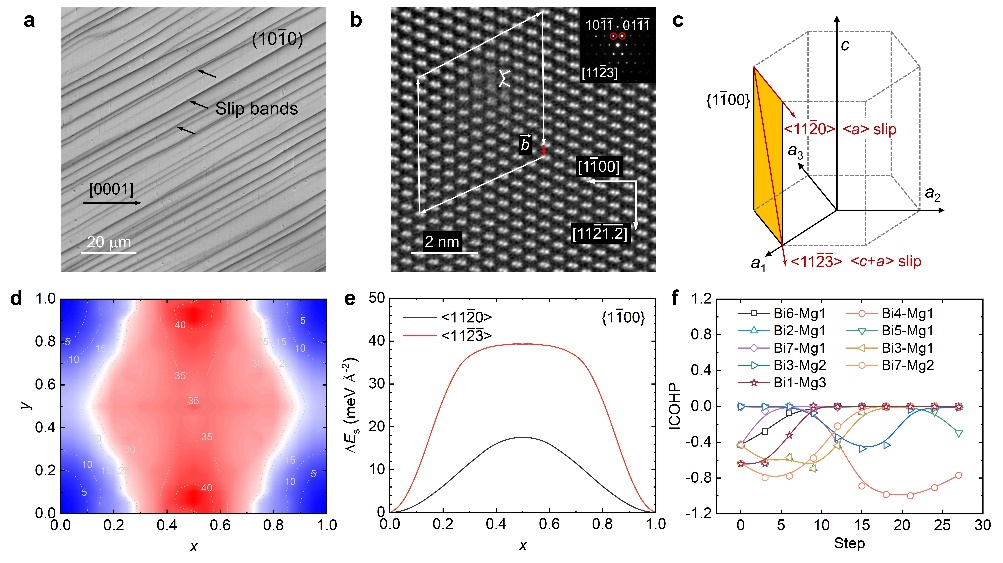

Fig. 2 Microstructural characterization of the deformed single-crystalline Mg3Bi2 and the first-principles calculations. SEM image of the deformed Mg3Bi2 (with 10% strain) showing sharp slip bands (a) and (b) dislocations. (c) The schematic view of the slip systems in Mg3Bi2. (d) Contour plot for the calculated slipping energy of plane. (e) Slipping barrier energy of plane along and directions,(f)-COHP for steps of slipping along direction.