A research team led by Professor Zhang Hongtao from the School of Materials Science and Engineering at Harbin Institute of Technology (Weihai Campus) has developed China's first dual-transducer solid-state ultrasonic additive manufacturing (UAM) equipment.

The equipment features a dual-head output power of 6,000 to 9,000 watts, enabling the high-quality fabrication of functional and gradient materials such as copper, aluminum, nickel, and titanium.

It also supports the composite additive manufacturing of dissimilar metals, such as copper/aluminum and aluminum/titanium. This breakthrough offers new process solutions for lightweight functional materials and non-destructive embedding of heat-sensitive components, with potential applications in aerospace, new energy vehicles, photovoltaics, and drone technologies.

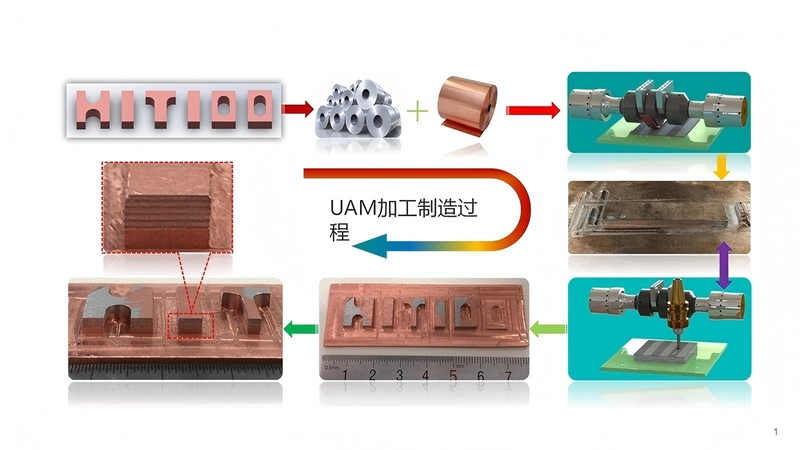

UAM is an advanced solid-state process that layers metal foils by using mechanical and thermal energy from high-frequency ultrasonic vibrations.

Compared to traditional fusion welding, UAM operates at lower temperatures, reducing oxidation, phase changes, and residual stress, making it particularly suitable for bonding dissimilar metals and fabricating functionally graded materials. However, conventional single-transducer systems have struggled with power limitations, especially for large and high-strength components.

The team began developing this concept in 2013 with support from major technological innovation projects in Shandong province and enterprises, including the Shandong Institute of Shipbuilding Technology and Weihai Wanfeng Magnesium S&T Development Co.

It initially proposed a heat-assisted ultrasonic rapid forming method and, in 2018, introduced a high-power push-pull ultrasonic rolling-weld consolidation process. Through iterative development, the team finalized a dual-transducer design featuring coaxial connection and dual amplitude rods to create a push-pull control structure on both sides of the welding head. This significantly improves energy efficiency and process stability.

The team also enhanced the system through resonance simulations, tooling surface optimization, and the development of an auxiliary platform. The prototype, which holds fully independent intellectual property rights, is now in its testing phase.

UAM manufacturing process. [Photo/hit.edu.cn]