A research team led by Professor Chen Ruirun from the School of Materials Science and Engineering at Harbin Institute of Technology (HIT) has made significant progress in developing a novel fully lamellar colony of TiAl alloys. These research findings have been published in Acta Materialia under the title A novel full lamellar colony (β1+γ) microstructure of Ti46Al5NbxFe alloys with high-density dislocations and nanotwins exhibited ultra-high strength and plasticity properties, providing new insights for developing next-generation lightweight aerospace materials.

Due to its low density, outstanding oxidation resistance, and remarkable creep resistance, the TiAl alloy is recognized as a highly promising material for achieving lightweighting and meeting high-temperature operating requirements in the aerospace field. However, the limited plasticity and poor hot workability of TiAl alloys limit their widespread application.

The team introduced Fe into TiAl alloys, creating a novel pearlite-like microstructure (β1+γ) featuring high-density dislocations and nanotwins, which improves both strength and plasticity. As the Fe content increases, a β1 phase enriched with Fe forms at the interface of the α2/γ phases and gradually replaces the α2 phase. The dislocations and interfacial energy at the α2/γ interface provide nucleation sites for the β1 phase. At the same time, the chemical non-equilibrium induced by the supersaturated structures formed when the Fe content reaches 2 percent provides the driving force for the growth of the β1 phase.

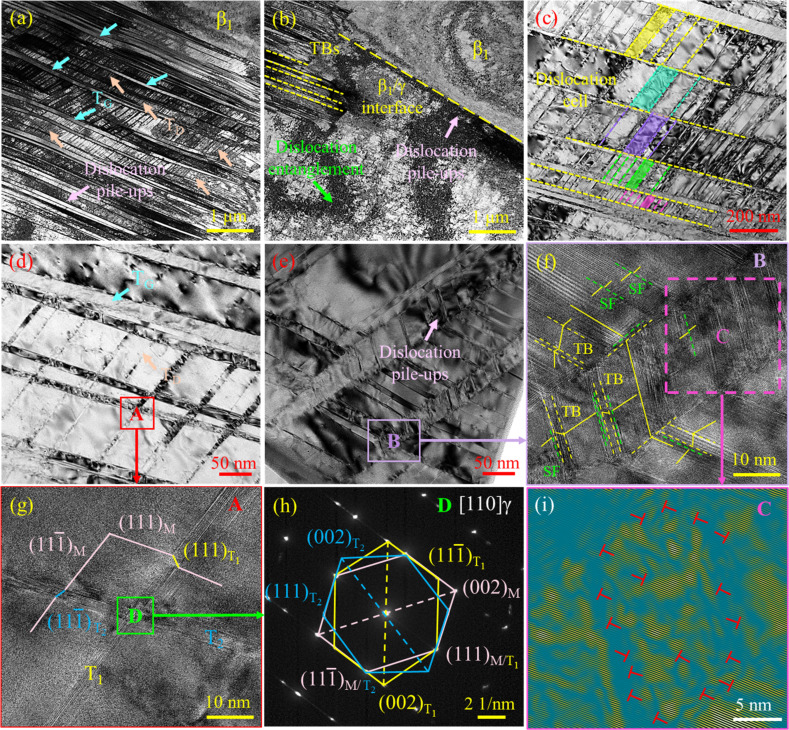

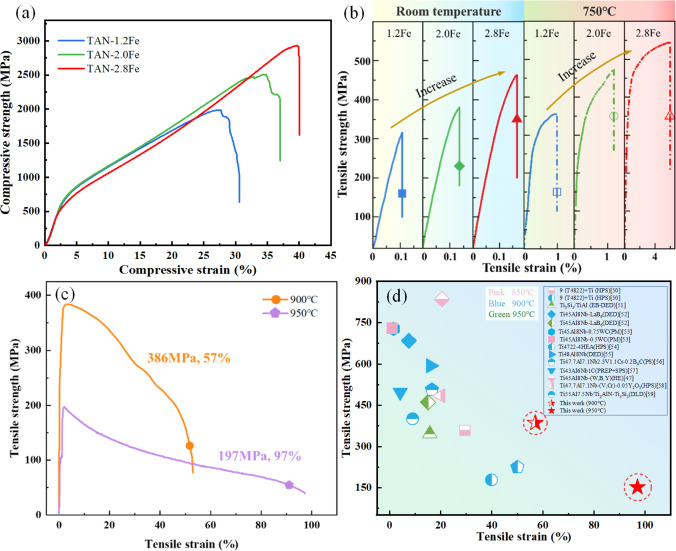

When the Fe content is 2.8 percent, the compressive strength and strain at room temperature reach 2925 Megapascal and 36.8 percent, respectively. The alloy exhibits an ultra-high tensile strain of 97 percent at 950 C, arising from the synergistic effects of texture weakening, activation of multiple slip systems, and continuous softening dominated by dynamic recovery and recrystallization. During the deformation process of the alloy under stress, high-density SFs and ultra-fine deformation nanotwins induced by the γ/β1 interface and twin boundary gradually form, promoting the formation of a 3D nanotwin network. Its inherent repeatability makes it a sustainable source for storing high-density dislocations. This special pearlite-like microstructure, together with plastic deformation mediated by SFs and nanotwins, as well as high-density dislocations, has established the experimental and theoretical foundation for TiAl alloys in plastic forming.

TEM results of Ti46Al5Nb-2.8Fe alloy after deformation. [Photo/hit.edu.cn]

TEM results of Ti46Al5Nb-2.8Fe alloy after deformation. [Photo/hit.edu.cn]

Mechanical properties and comparison of tensile properties with other TiAl alloys. [Photo/hit.edu.cn]

HIT is the sole corresponding affiliation for this paper. The first author is Zhou Lingyan, a doctoral candidate at HIT's School of Materials Science and Engineering, with professors Chen and Fang Hongze serving as corresponding authors.

The research has received support from the National Natural Science Foundation of China and other funding programs.