Written by: Wang Ji

Translated by: Zhao Yuhang

Edited by: D. Parker

Date: 5-21

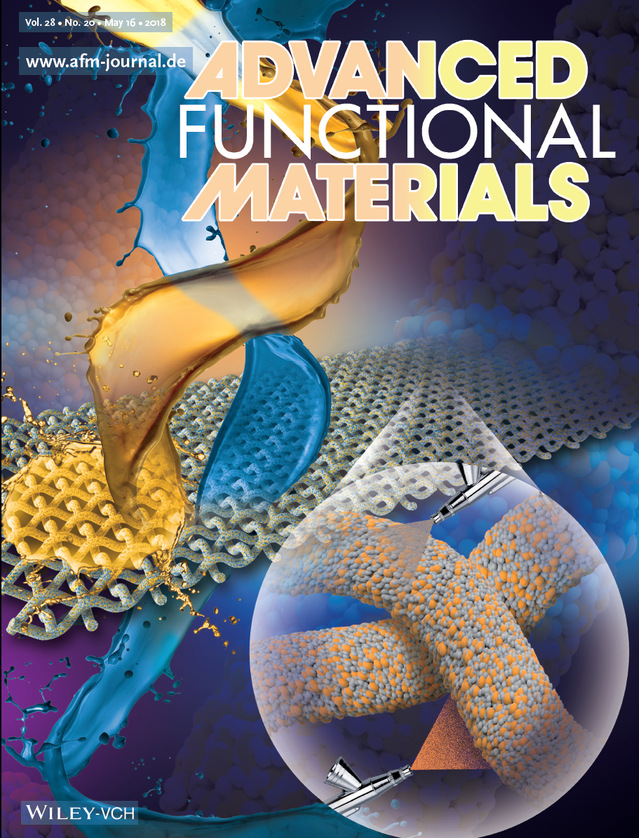

Recently, the team of Professor Zhao Xuezeng and Associate Professor Pan Yunlu of the School of Mechanical and Electrical Engineering have made progress in the selection of wettability functional materials for oil-water separation and controllable actuation of droplets. The research results were published as a back cover article in “Advanced Functional Materials” (Impactor factor 12.124). HIT was the only signatory unit of the paper.

Oil-water separation is of great significance in many fields. The use of momentum filtration for oil-water separation has the advantages of high speed and low energy consumption. However, due to the relatively high surface energy of water, existing oil-water filtration separation technology adopts a filtration method by “water-blocked and oil-free.” The mesh pores are easily blocked by high-viscosity oil or sealed by a high-density water film. This leads to the stagnation of the fluids. These defects greatly limit their application.

By constructing a special micro-nano composite structure, the research team overcame the limitations of the traditional theory of surface energy. They prepared an ultra-wetting functional coating, which is completely oil-free yet completely hydrophilic. By applying this kind of coating to the mesh substrate, oil-water separation with “water-blocked and oil-free” occurs. This solves the problems of “water-blocked and oil-free” filtration. The prospects for application are numerous. There is important practical value in industrial sewage treatment, crude oil exploitation and marine oil pollution recovery.

"Advanced Functional Materials", current edition (May 16, 2018, 28 volume 28, issue 20), back cover note: “In article 1706867, Pan Yunlu et al. proposed an efficient method for preparing ultra-hydrophobic super hydrophilic coatings. The coating can be used to achieve oil-water separation, oil absorption and oil droplets in controlled transport. At the same time, the concrete-like structure they proposed significantly improved the mechanical strength of the coating.