Written by: School of Astronautics

Translated by: Li Zebing

Edited by: William Mosteller

Date: 2019-11-14

Harbin Institute of Technology News (School of Astronautics/Text) Implantation of occlusion devices is an effective method to treat structural heart disease. However, most of the commercial occlusion devices are made of non-degradable nickel-titanium alloy, and there are various complications, such as metal ion precipitation, allergy to the material, corrosion of the material and so on. Therefore, it is an urgent problem to develop a biodegradable, biocompatible, and deployable cardiac occluder.

In view of the above problems, Professor Leng Jinsong's research group of the Institute of Composite Materials and Structures, part of the School of Astronautics of our university, recently published an article entitled "4D-Printed Biodegradable and Remotely Controllable Shape Memory Occlusion Devices” in Advanced Functional Materials. In this study, a customizable, biodegradable, and remotely driven shape memory polymer occluder was designed and fabricated by combining programmable shape memory polymer with 4D-printing technology, which is expected to be a potential replacement for metal occluders. The first author of the paper is Lin Cheng, a doctoral student of our university, and the co-authors are Professor Leng Jinsong and Professor Liu Liwu. The study was strongly supported by Fu Lu, Li Yuanshi, and Lu Jinxin, Ph.D. candidates of the First Affiliated Hospital of Harbin Medical University.

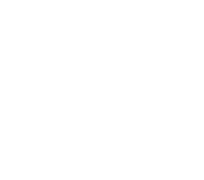

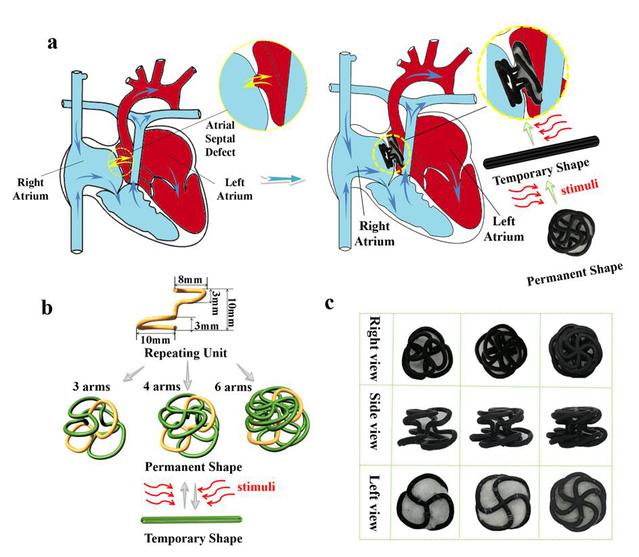

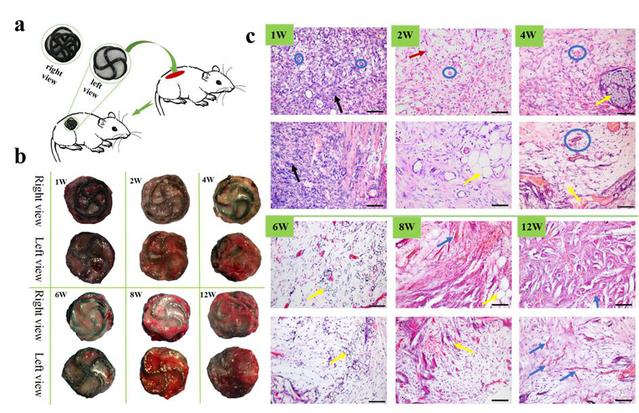

Taking an atrial septal defect (ASD) occluder as an example, a programmable shape memory ASD occluder was designed. The occluder is comprised of a frame-type support structure and a flow barrier film, and magnetic nanoparticles are introduced to realize the remote controllable expansion of the structure. Optimizing the geometric parameters of the frame achieves a high storage ratio and excellent mechanical properties of the structure. The loading capacity of the occluder was evaluated by simulating human body loading conditions. In vitro cell culture and in vivo implantation experiments showed that the occluder had good biocompatibility, which was beneficial to cell adhesion and the growth of new tissue into the occluder, and was helpful for the rapid endothelialization of the occluder. H&E staining results showed degradable particles visible two weeks after implantation (Fig 2), confirming the degradability of the occluder. Feasibility verification shows that the occluder can quickly and completely realize the programmed recovery and plugging process (Fig 3). This work takes the ASD occluder as an example, and other types of occluder devices can be designed and manufactured in a similar manner.

Fig 1 (a) is a schematic diagram of an ASD and an occluder implantation process, along with the design drawing of the occluder (b); (c) 4D Print Shape Memory Occluder

Fig. 2 (a) an occluder implantation process; (b) that post-implantation occluder and the surrounding adhesive tissue; (c) H&E stain pattern of tissue around that occluder at different times after implantation

Fig. 3 4D print that programmed recovery of the shape memory polymer occluder (a) under an applied magnetic field; (b) Functional verification

Professor Leng Jinsong's team has long been engaged in shape memory polymers (Mat Sci Eng C-Mater 2019, 97, 864; Chinese Science: Technical Science, 2018.48 (08): pp. 811-826) and the bio-application of 4D-printed active controllable smart devices (Chinese Science: Technical Science, 2019.49 (01): pp. 13-25; Chinese Science: Technical Science, 2018.48 (125): 2-16), which include 4D-printed tissue scaffolds, tracheal scaffolds (Composites Part A 2019, 125, 105571; Acs Appl Material Inter 2016, 9, 876), structural design and mechanical analysis (Compos Sci Technol 2019, 107866), and functionalization (Carbon 2019, 155, 77, ACS Appl Materl Interfaces 2019, 11, 24523).

Link to paper: https://onlinelibrary.wiley.com/doi/10.1002/adfm.201906569