Professor Lijun Yang’s team at the School of Mechanical and Electrical Engineering of Harbin Institute of Technology has precisely regulated the electrochemical performance of zinc anodes using ultrafast laser micro-nano manufacturing technology. Their research, titled Ultrafast Laser One-Step Construction of 3D Micro-/Nanostructures Achieving High-Performance Zinc Metal Anodes, has been published in PhotoniX, providing new insights into the practical application of ultrafast laser micro-nano manufacturing technology in the field of zinc-based energy storage.

Zinc metal is a promising anode material for aqueous zinc-ion batteries due to its abundant storage capacity, non-toxicity, environmental friendliness, low electrochemical potential, and high theoretical capacity. However, during the cycling process of aqueous zinc-ion batteries, uncontrolled dendrite growth on the zinc anode surface and harmful corrosion/side reactions significantly shorten device performance.

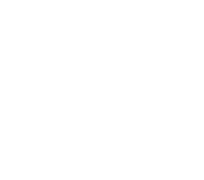

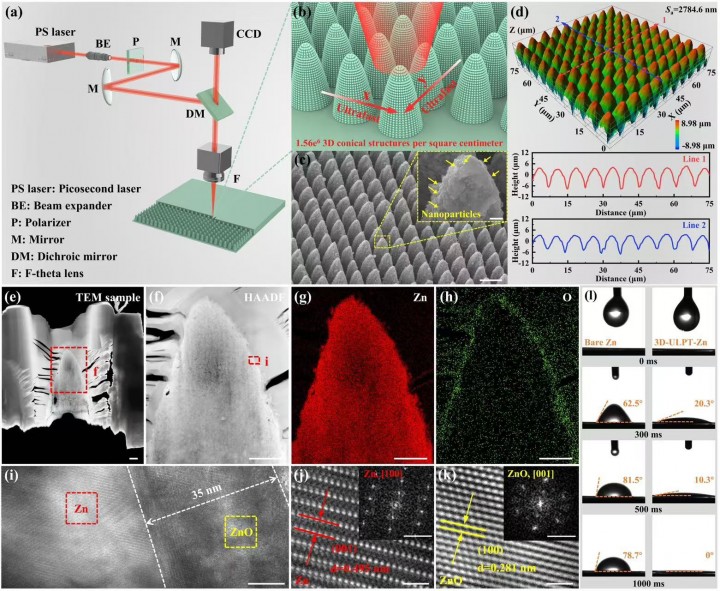

To address these issues, the team employed an ultrafast laser one-step fabrication method to construct functional three-dimensional micro-/nano structures on the surface of zinc metal anodes, effectively resolving the problems of dendrite growth and corrosion/side reactions associated with zinc anodes. The three-dimensional micro-/nano structures integrate low local current density, rapid zinc ion transport, and ultra-high zinc deposition space, optimizing the electric field distribution, zinc ion concentration distribution, and nucleation behavior of zinc on the electrode surface. This results in uniform zinc deposition and suppression of corrosion/side reactions, demonstrating excellent electrochemical performance and flexibility in practical applications. This innovative method offers a new approach for constructing three-dimensional micro-/nano structures on metal electrode surfaces to achieve high-performance energy storage devices.

Paper Link: https://photonix.springeropen.com/articles/10.1186/s43074-024-00122-x