Reported by: Zhang Yan

Translated by: Pang Yue

Edited by: Garrick Jones

Nowadays, under the subsidy of NSFC, the research group led by Professor Wang Chunqing of national key laboratory of advanced welding and connection in the School of Material Science realized the metallurgical interconnection with high reliability between nano array structure on surface and nano interconnector, solving the contradiction of incompatible microscale between traditional pad structure and new-type nano interconnector in the connection process and providing new interconnecting technique for semiconductor power/high temperature device package of the third generation and three-dimensional packaging manufacturing. The research paper entitled “the method of making up the array of three-dimensional nickle nano lance and mace with one step as well as the firing and the interface analysis of nano silver” was published in the journal “Applied Materials & Interfaces” under ACS (influence factor of 7.145). HIT is both the first signature unit and the first corresponding author unit.

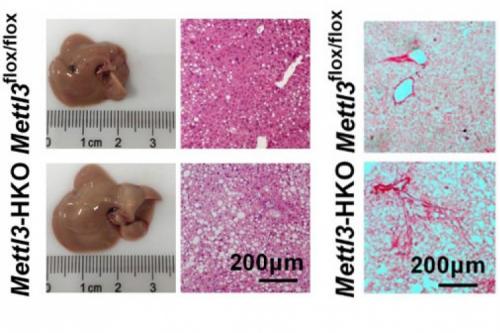

As a new interconnector, metal nanopowders are gradually replacing conventional solder in high temperature electronic packaging and power module package, being the frontier material internationally and coming into use. However, the actual time and temperature of the connecting is much higher than the theoretical prediction. The nano connecting material and substrate is incompatible in surface structure and energy. Based on the nanometer size effect, rapid mixing can be achieved among nano powder particles. By contrast, the mixing rate between nano connecting material and flat substrate is much slower than the former rate. In the actual connecting process, there exits the incompatible problem between self sintering process of nano powder particles and the connection between them and substrate. The research group proposes that by adjusting the energy of substrate surface to match the energy substrate surface and nano connecting material, the good compatibility can be achieved in the connecting process between new-type nano connecting material and conventional substrate. Besides, the research group also develops the method of direct electrodeposition without template to make up the array of three-dimensional nickle nano lance and mace on the surface of the traditional copper pad. It founds that under conditions of no atmosphere protection and extra pressure, the nano array and nano silver connecting material can create reliable metallurgical bonding, rapidly and there is no obvious hole in the join. Chemical potential calculation proves that compared with the traditional macro scale, the nano array on surface and nano connecting material is more compatible in energy. The nano array on pad surface can effectively achieve the transformation of nano materials since the sintering process changes the connection process and sintering materials from self sintering process to the connecting between nano array and its connecting material as well as the competition between the connection and self sintering. Such action realizes the compatibility of microscale of connecting process, raising 6 times the cut intensity of the joint. The study is expected to be a new hotspot in the area of electronic packaging interconnected structures.

The link of the paper: http://pubs.acs.org/doi/full/10.1021/acsami.6b13031