Written by: JI Xing, SHANG Yankai

Translated by: JI Shujie

Edited by: William Mosteller

Date: 12-29

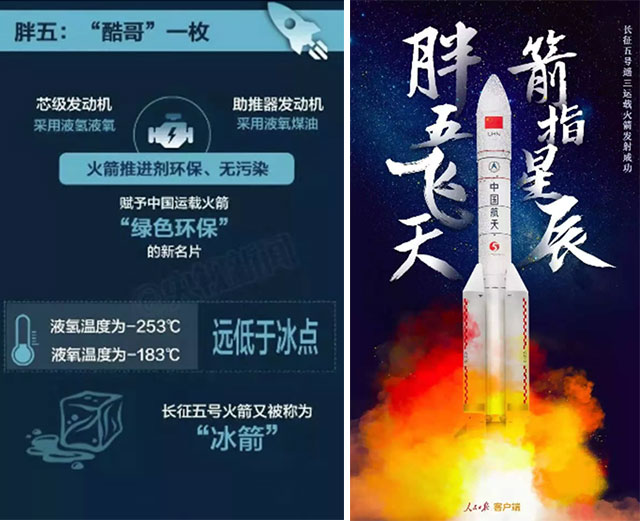

At 20:45 on December 27, the new carrier rocket, Long March 5, with the largest thrust in China's Long March rocket family, blasted off from Hainan Wenchang Launch Center and successfully sent the 20 experiment satellites into their planned orbits.

From the first successful flight on November 3, 2016 to today's launch, many Harbin Institute of Technology technicians and designers have devoted their time and played an important role. Let's learn about the power of Harbin Institute of Technology behind the successful launch of Long March 5.

The total thrust of Long March 5 reached 1000 tons. Academician WANG Zhongqi and Professor FENG Guotai of the Engine Aerodynamics Research Center of our School of Energy have a project named “Turbine Aerodynamic Design of 120 Tons of Liquid Oxygen and Kerosene Engine with boost ”, which has played an important role in the development of the rocket’s thrust.

The Long March 5 used core engines during the first and second core stages, boosters, and auxiliary power systems to jointly undertake the power support tasks in all aspects of the flight test. These provided a total thrust of 1078 tons, including eight 120-ton liquid oxygen and kerosene engines.

Academician WANG Zhongqi's team undertook the turbine design of the booster stage engine and carried out the aerodynamic design of the turbine of the 120-ton liquid oxygen kerosene engine of the booster stage. The design uses curved blade technology and comprehensive optimization flow pattern design method. The design process is based on the turbine aerodynamic design system independently developed by the Engine Aerodynamic Research Center of our school, which greatly improved the capacity of the turbine and solved the key problem of lack of driving force between the turbine and the pump. This type of engine performed perfectly in the first flights of Long March 7 and Long March 6.

Professor JIANG Hongyuan's team from the Institute of Metal Rubber Technology in our School of Mechatronics solved the Long March 5’s problem of damping vibration attenuation under extreme working conditions such as high vacuum, large temperature difference, and strong radiation. The metal rubber damping ring has designable damping performance, and its combined structure can realize vibration isolation of equipment under complex mechanical environment conditions.

Relying on our research and development foundation and advantages, the Institute of Metal Rubber Technology has focused on the country's major needs and aimed at technical bottlenecks to produce metal rubber components that meet different working conditions and structural requirements. Some metal rubber components have successfully replaced imported components on important equipment and have been successfully applied in the Chang 'e-3 lander and other missions.

In addition to technical support, the young teacher ZHU Lei’s design team also worked on the logo design of Long March 5. It was introduced that the idea for the design came from a Tai Chi pattern in traditional Chinese culture, which presents a dynamic image of “5”. It symbolizes that the Long March 5 rocket seeks comprehensive optimization of multiple factors such as performance, reliability, economy, safety, and environmental protection. At the same time, its circular outline symbolizes the relationship between the brand and the sky, and suggests the complete success of the Long March series of rockets. For the overall color, the red Long March 5 logo echoes the national flag, which presents a visual impression dominated by red at the base of the largely white rocket. It strengthens the dominant position of Chinese elements from the perspective of visual communication. The overall painting form and color convey the visual semantics---China is a big country.

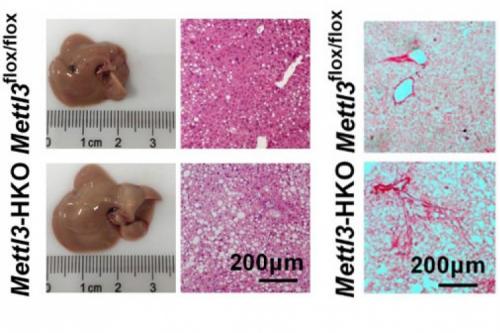

Professor HE Xiaodong's team from the Institute of Composite Materials and Structures in our School of Astronautics has a project named "Thermal Protection of Engine Cylinders". It successfully developed a lightweight and efficient thermal insulation felt composite protection structure to overcome the thermal protection problem of Long March 5.

The research team adopted the material optimization design method and gave full play to the characteristics of fiber materials. A new type of thermal protection material was developed, which is lightweight, flexible, and thermally insulated. This material has special distribution of fiber, low density, and excellent thermal insulation. It is characterized by three-dimensional curved surface bonding, flame retardancy, and no moisture absorption. The material provides thermal protection for engine cylinder components and cylinder supports, as well as reduces radiation heat transfer and convective heat transfer formed by plume. It also prevents the cylinder shell from heating too much. In general, it successfully solves the thermal protection problem of rockets, and contributes to the successful flight of Long March 5.