A research team led by Professor Zhimin Fan from the School of Chemistry and Chemical Engineering at the Harbin Institute of Technology (HIT), in collaboration with the National Key Laboratory of Space Power Sources, has developed a novel high-temperature ultrasonic exfoliation technique that enables efficient, high-yield production of monolayer MXene—a milestone for industrial-scale applications in wearable electronics, energy devices, and beyond. The study, titled “Scalable, High-Yield Monolayer MXene Preparation from Multilayer MXene for Many Applications”, has been published in Angewandte Chemie International Edition.

The Promise and Challenges of MXene

MXenes, a family of two-dimensional (2D) materials known for their exceptional conductivity, hydrophilicity, and mechanical strength, are revolutionizing fields such as energy storage, aerospace, and flexible electronics. However, industrial adoption has been hindered by low yields, inconsistent quality, and the difficulty of isolating single-layer MXene sheets from their multilayer precursors.

Innovative Exfoliation Strategy

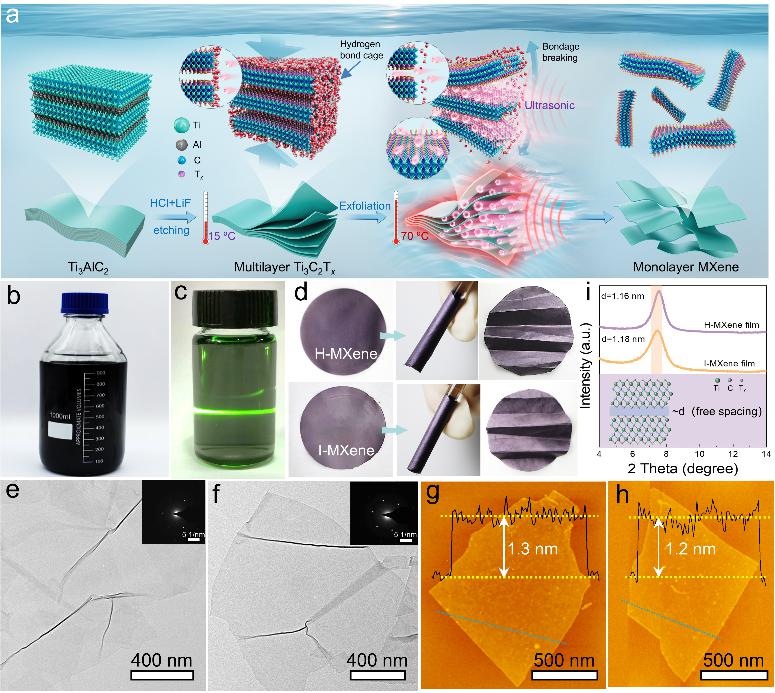

The team discovered that hydrogen-bonded cage structures formed between oxygen-containing functional groups on multilayer MXene surfaces and water molecules were the key barrier to efficient exfoliation. By applying moderate ultrasonic power at 70°C, they weakened these hydrogen bonds, allowing cavitation-induced microbubbles to penetrate and gently separate MXene layers. This method achieved:

95% yield of monolayer MXene—far surpassing conventional techniques.

Rapid processing (completed in tens of minutes).

Large, high-quality sheets suitable for industrial applications.

Scalability and Applications

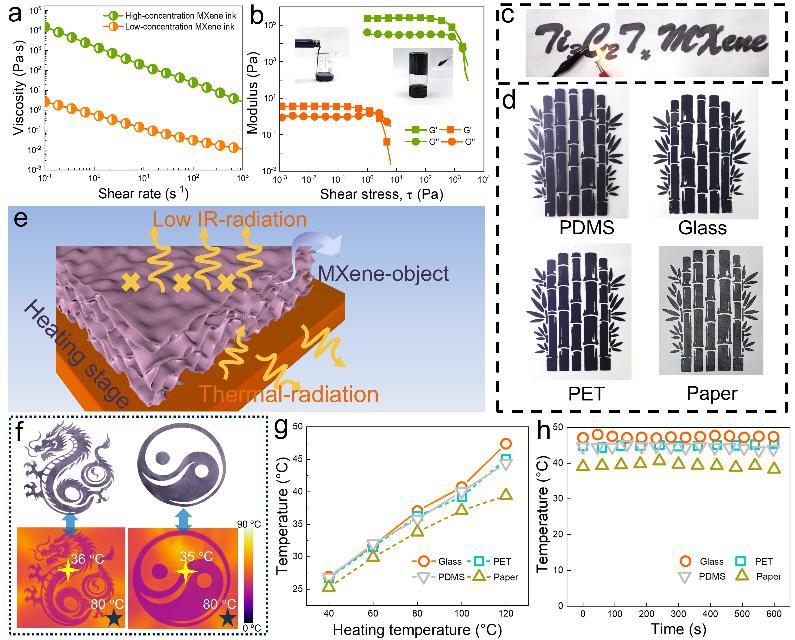

The high-yield monolayer MXene exhibited physical and chemical properties identical to those produced by traditional methods, ensuring reliability. The team successfully scaled the process to 100-gram batches with over 90% yield, demonstrating feasibility for mass production. High-concentration MXene inks showed superior printability, enabling advanced applications like infrared stealth coatings and high-efficiency Joule heating devices.

“This breakthrough addresses the critical bottleneck in MXene commercialization,” said Professor Fan. “Our technique not only boosts yield but also ensures consistency, paving the way for MXene’s integration into next-generation technologies.” The work positions MXene as a viable material for scalable manufacturing, accelerating its adoption in smart textiles, flexible sensors, and energy storage systems.

Paper link: https://doi.org/10.1002/anie.202418420

Figure 1. Schematic illustrating the high-yield preparation of monolayer MXene by efficiently dissociating the hydrogen-bonding cage confinement of multilayer MXene through high-temperature sonication

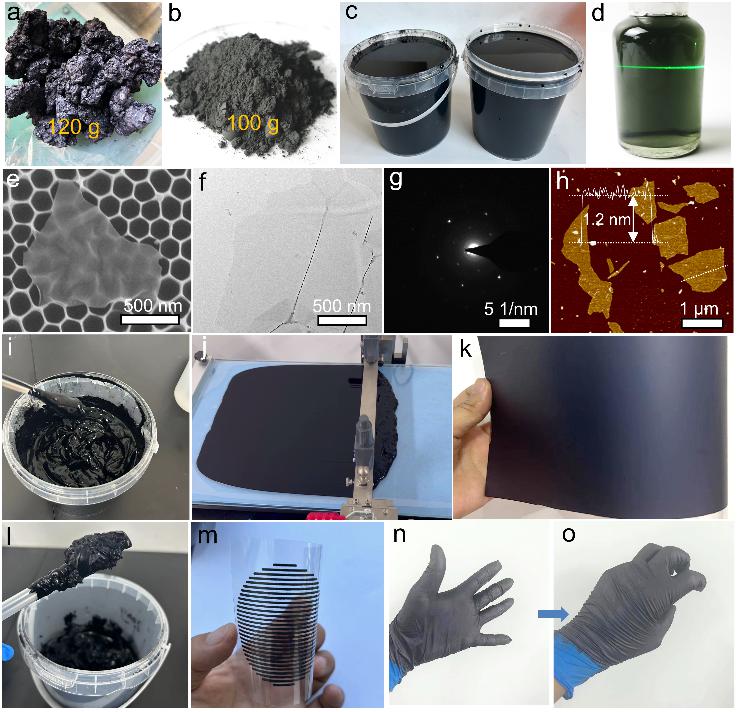

Figure 2. Large-scale synthesis of monolayer MXene microstructures and macroscopic assemblies using the high-temperature ultrasonic exfoliation method

Figure 3. Large-scale synthesis of monolayer MXene for the demonstration of printed devices